Fueling Innovation at Beta in Bentonville: Empowering Startups Through CAD Design and Functional Prototyping

The Beta in Bentonville Product Prototyping Lab, operated by the University of Arkansas, is dedicated to supporting Arkansas startups with CAD design and functional prototyping services. The lab is equipped for metal machining, fabrication, and metal 3D printing, and is staffed by a full-time machinist and College of Engineering students. Beyond aiding the entrepreneurial ecosystem, the lab offers hands-on experience for engineering students, supports the Masters of Science in Product Innovation (MSPI) program, and collaborates with Bentonville high school students and the Scott Family Amazeum to share resources and expertise.

Beta In Bentonville Equipment

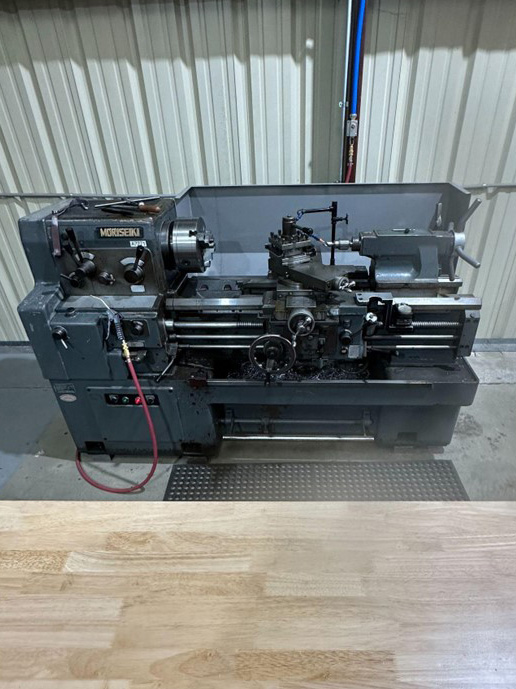

Machining Capabilities

- X axis 30.00 in. Y axis 16.00 in. Z axis 16.00 in.

- Spindle Speed - 7.5 hp 6000 rpm max

- Table Size - 10.5” x 47.8”

- Automatic Tool Changer - 20 station carousel

- Travel - X axis 30.00 in. Y axis 12.00 in. Z axis 20.00 in.

- Spindle Speed - 0-5000 rpm

- Table Size - 10.00 in. 50.00 in.

- Travel - X axis 8.00 in. Z axis 45.00 in.

- Swing - 17.5”

- Spindle Speed - min. 54 rpm max. 3000 rpm

We can machine a wide variety of materials; plastics, carbon steels, tool steels, stainless steel, aluminum, titanium, brass, and copper.

Metal Fabrication Capabilities

- Travel - X axis 28.00 in. Y axis 36.00 in.

- Material Thickness - .750 in max.

- Cutting Speeds - 300 IPM max.

- Table Size - 20.00 in. x 20.00 in.

- Workpiece Size - 18.00 in. blade to upright

- 10.00 in. max. Height

- 9.00 in. max dia.

- 8.00 in. x 8.00 in. max block

- Tube Sizes - ¾” - 2” dia.

- Angle Range - 0 deg. - 90 deg.

We also have an Oxy Acetylene cutting torch available for metal fabrication as well.

3D Printing Capabilities

- Chamber Size - 10.00 in. x 10.00 in. x 10.00 in.

- Max Print Size - 9.40 in. x 9.5 in x 10.00 in

- Materials - ABS, PLA, PTEG, PTEG CF, TPU 95

- Chamber Size - 10.00 in. x 10.00 in. x 10.00 in.

- Print Size - 10.00 in. x 10.00 in. x 10.00 in.

- Materials - aluminum, stainless steel, and titanium.

CAD Design

- Solidworks - CAD Modeling, Drawings, Assemblies, Simulation, and Analysis

- GibbsCAM - 2.5D and full 3 axis CNC programming

- Fusion 360 - CAD Modeling, Drawings, and Assemblies

- Fusion 360 CAM - 2.5D and full 3 axis CNC programming, Plasma 2 axis Programming

- Fusion 360 NETFABB - Support software for metal 3D printing

Beta in Bentonville also serves as a front door to Arkansas based startups for area resources and companies that can handle projects that are beyond our scope with either size or capabilities. Beta in Bentonville staff have made connections with other UA facilities as well as local and regional manufacturing facilities that are equipped for small to large scale production.

Are you an Arkansas start-up in need of product prototyping assistance?

For questions, email us at brrogers@uark.edu